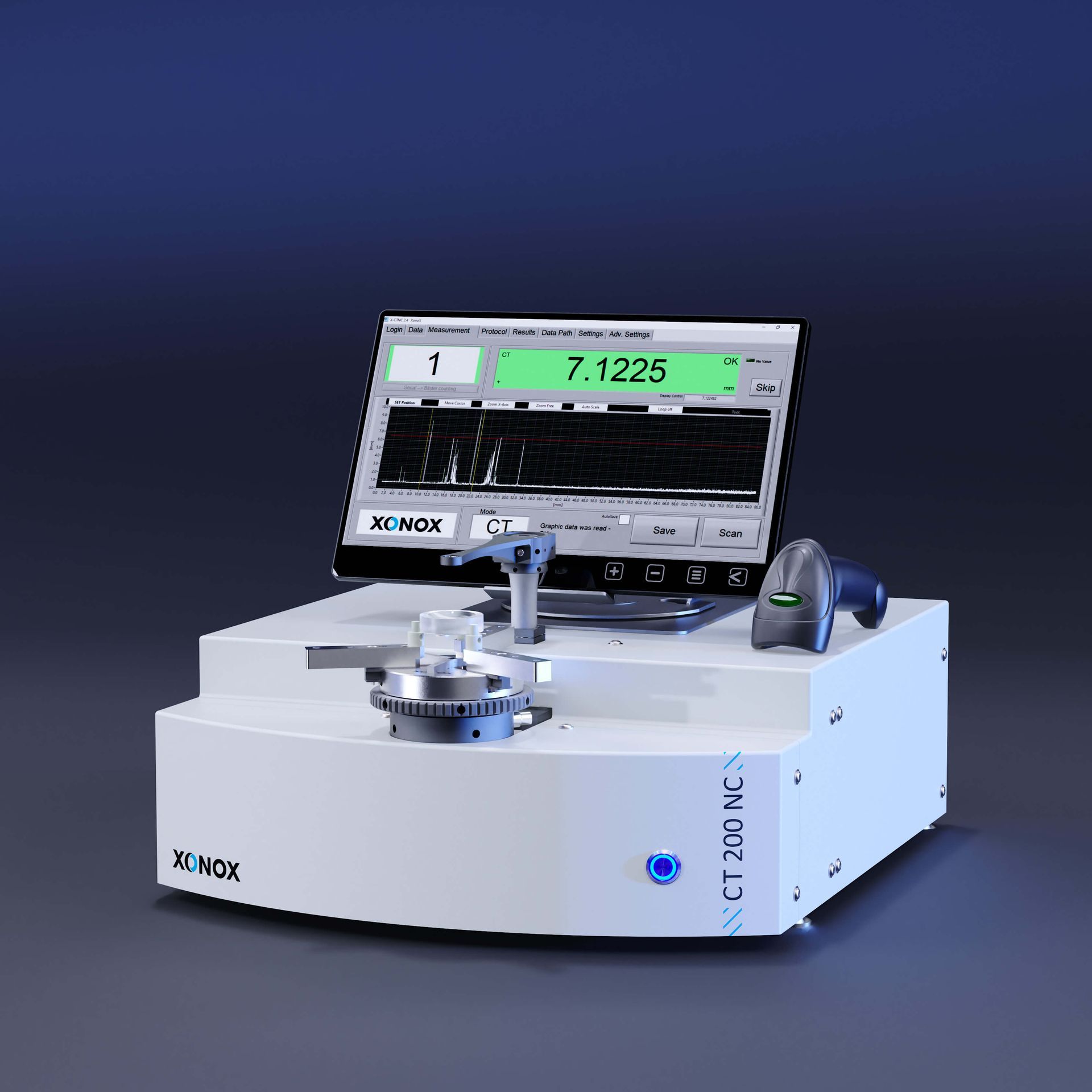

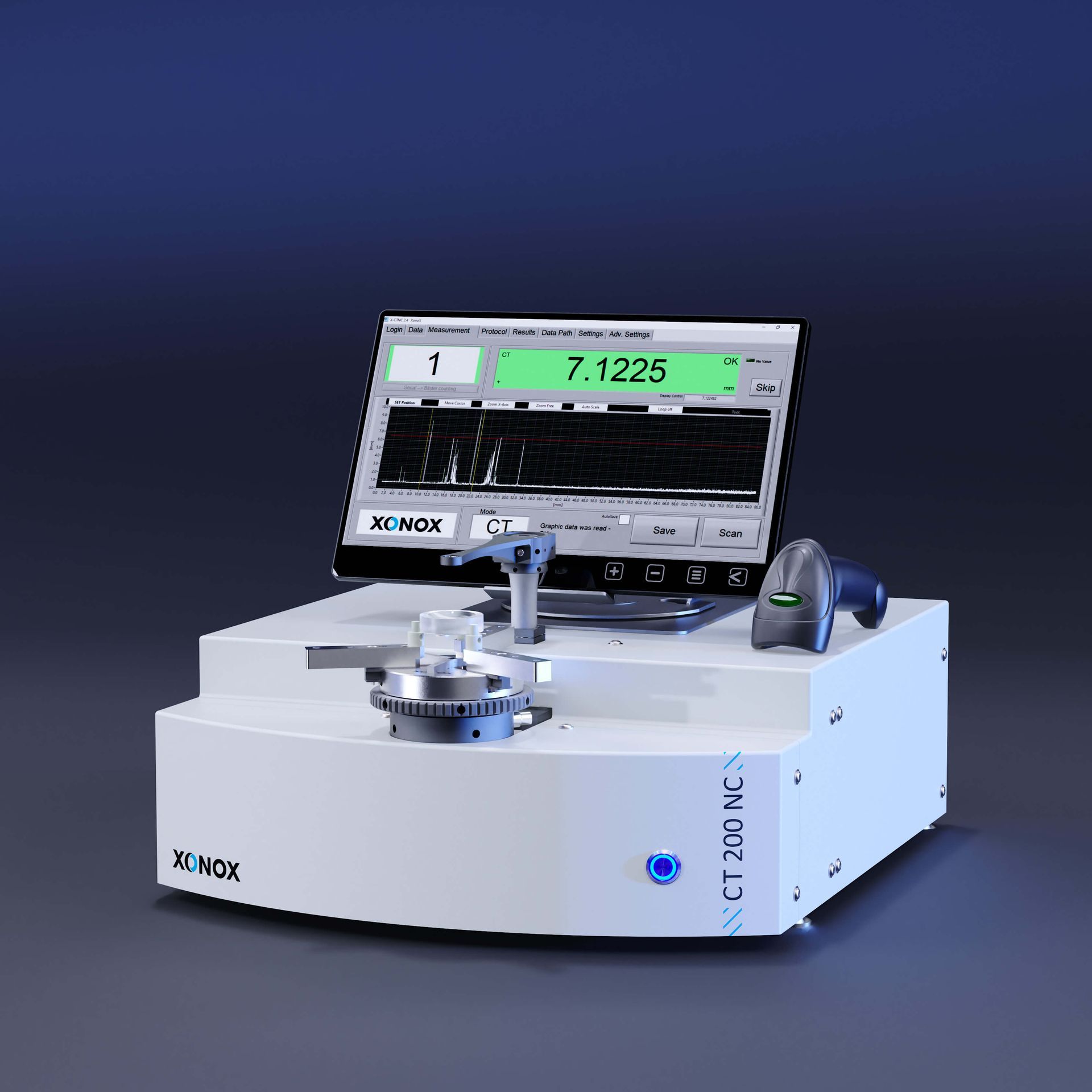

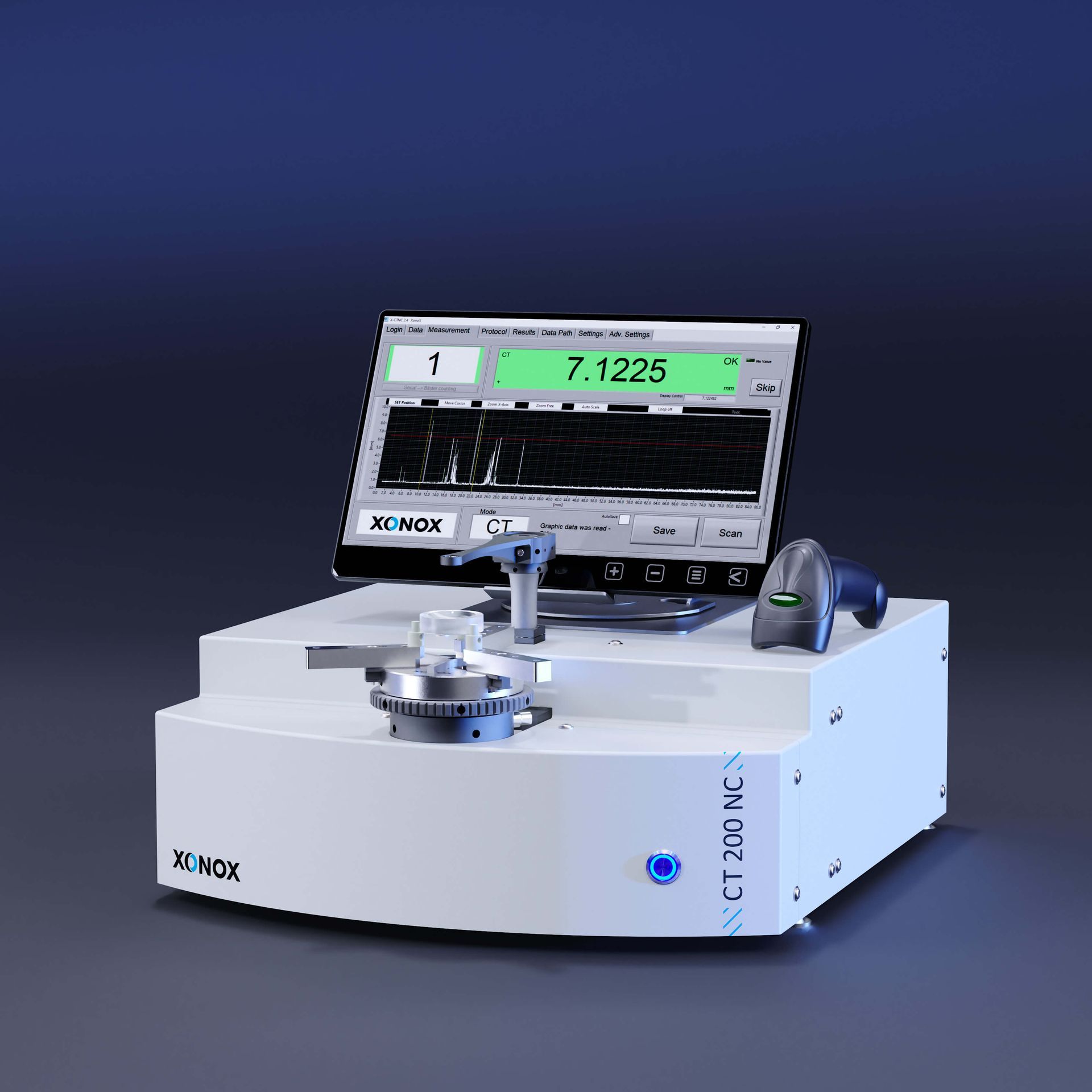

CT-SAG-Aperture-Height

NON-CONTACT

CENTER THICKNESS MEASUREMENT SYSTEM

- highly precise and easy to use non-contact system for measuring the thickness of optical elements in both, production and quality inspection environments

- integrated interferometric sensor for fast, reliable and high precision thickness measurement

- measurement of single elements and assemblys

- lenses automatically centered with an innovative precision 3-jaw chuck system

- measurement of elements with one side access only is accom-odated. Ideal for testing lenses - even mounted to holders - with demanding CT tolerances in the polishing operation

- measurement of SAG depth, surface aperture diameter, total lens height and stock removal are supported in addition to CT measurement

- ergonomically positioned lens holder provides for safe, easy and fast loading and setup of workpieces up to ⌀200mm

- extensive integrated glass database provides ready access to index data. Software supported Index finding device allows for easy and quick automatic analysis of unknown index values

- easy and touch screen optimized dialouge user interface

- automatic numbering of lenses, IN/OUT if spec colors

- full glass database for index settings

- live display of measuring signal - zoomable by finger tip

- intelligent and easy-to-use setup for administrative functions and

user handling - quick setup for auxiliary equipment such as QR reader, footswitch etc.

- easy network integration and path settings for documentation

- single lenses and flats

- micro optics

- various

- UV-VIS-IR materials

- lenses on holders

- protection painted lenses

- lenses sticked on polishing chucks

- cemented lenses

- components with access to only one side