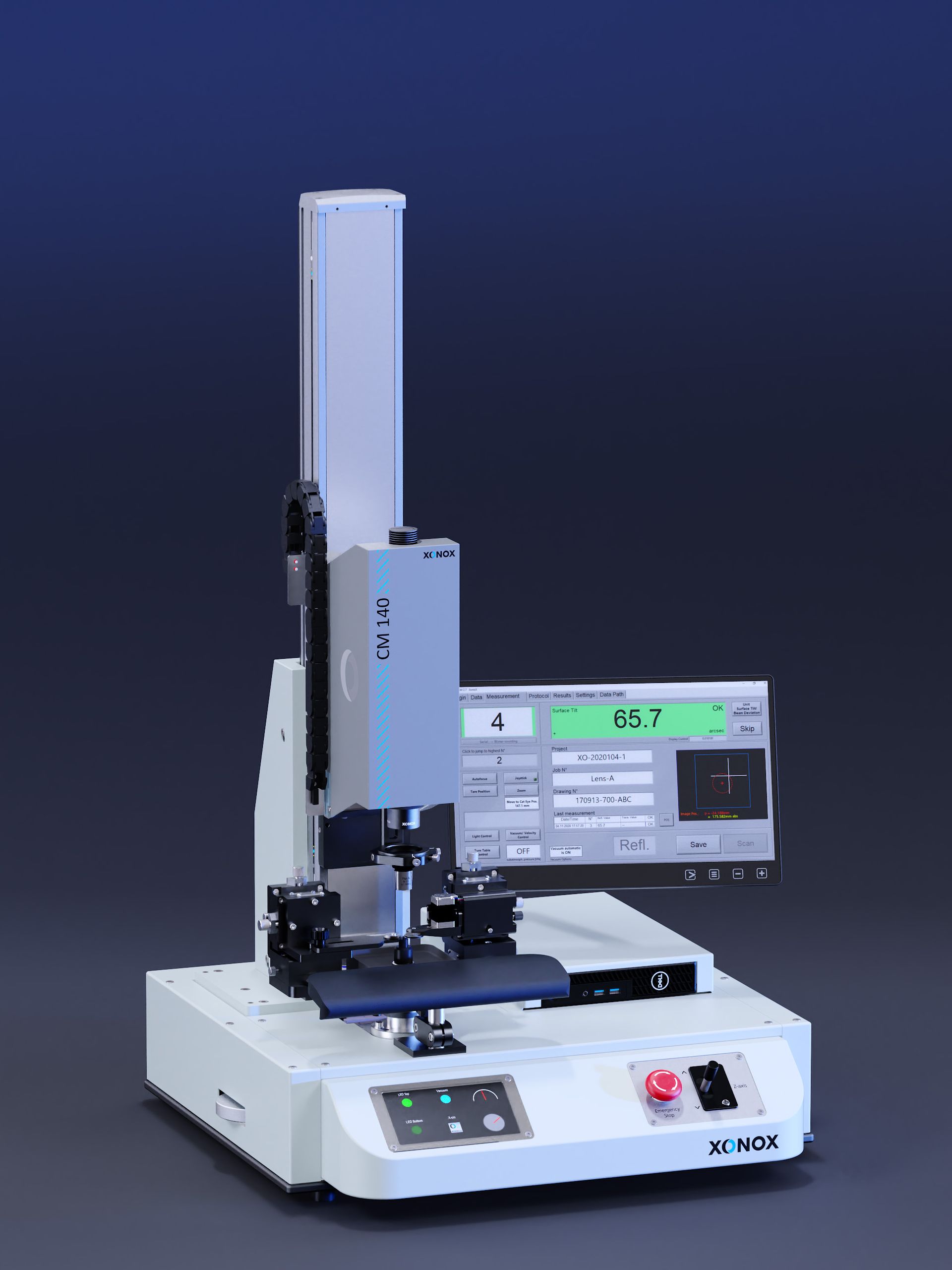

Centration // Wedge

CENTERING ERROR MEASUREMENT AND DOUBLET CEMENTING SYSTEM FOR MICRO OPTICS

- automatic z-axis positioning plus software supported electronic motion- and vacuum control, linked to specific job

- additional HR screen, displaying actual status of rotation-, led- and vacuum level

- precise and easy to operate non-contact measurement system for determining centering errors on lens elements in production, quality inspection or metrology lab environments

- measurements facilitated by precision autocollimator and secondary substage collimator

- software recall of previous setups facilitates efficient use for recurring jobs

- lens centering can be measured in transmission or reflection

- unique, multi axis lensholder, securely centers microlenses of various diameters and correcly locates friction wheel for efficient loading and operation

- very fast and convenient setup of lensholder adjustable for normal lenses and rod lenses

- commonly used functions are conveniently located for easy access and direct control over Z-axis height, vacuum, speed, crosshair display

- equipped with "X-cm", an extensive software and controller package, that offers various operating modes and provides automatic measurement results of complete series

- cementing of doublets and triplets by using additionally available accessories such as glue dispensers and UV light sources